Earthing Accessories

Previous : Earthing Accessories

Instruction

♦ Ex / ATEX directive European Certified TSTLP® Isolating Spark Gaps (ISG) are designed to apply for lightning protection equipotential bonding ( Connection) , like Cathodic protection, especially for the separated earthing systems using in Hazardous Areas with Safer Lightning Protection.

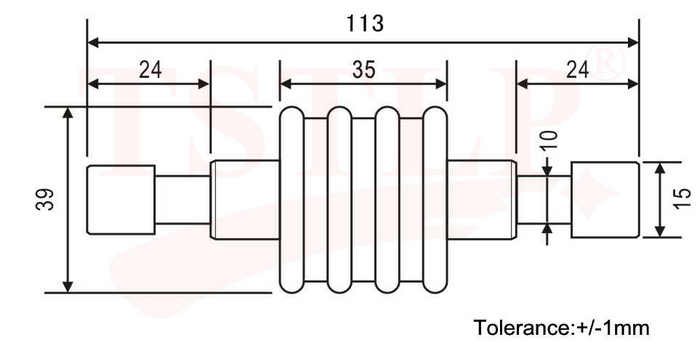

♦ Product Size of TSTLP Isolation Spark Gap

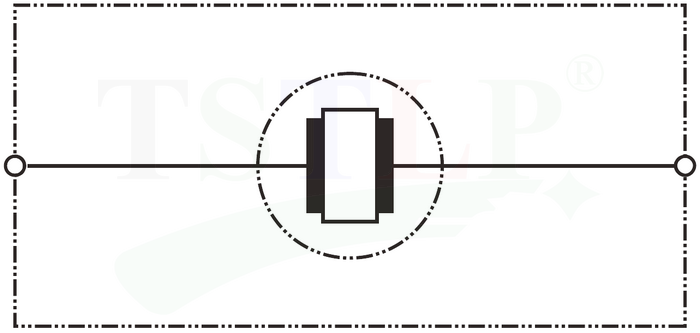

♦ Basic Circuit Diagram of TSTLP Spark Gap Arrester

♦ Technical Data of TSTLP Isolating Spark Gaps

|

Model Number |

TS-ISG25 |

TS-ISG50 |

TS-ISG100 |

|

Lightning impulse current (10/350 µs) [Iimp] |

25kA |

50kA |

100kA |

|

Nominal discharge current (8/20 µs) [In] |

100kA |

100kA |

100kA |

|

Rated power-frequency withstand voltage (50 Hz) [UW/AC] |

250V |

250 V |

250 V |

|

100% Lightning impulse sparkover voltage [Urimp] |

≤ 1.25kV |

≤ 1.25kV |

≤ 1.25 kV |

|

Power frequency sparkover voltage (50 Hz) [Uaw] |

≤ 400V |

≤ 400V |

≤ 400V |

|

Operating temperature range [TU] |

-40°C / -20°C...+60°C |

||

|

Relative Humidity |

≤ 95% (250C) |

||

|

Degree of protection |

IP66/67 in accordance with lEC 60079-0 & IEC 60529 |

||

|

Enclosure material |

Black / Orange Thermoplastic UL94-V0 |

||

|

Connection |

Rd 10 mm |

||

|

Material (connection) |

Cu/SS |

||

|

Verify Certificate by using code ECM 22 ATEX-B SD96 |

http://certificate.entecerma.it/it/VerificaCertificato.aspx# |

||

|

Standards Compliant & Certified |

IEC 60079-0 IEC 60529 EN IEC 60079-0:2018 EN 60079-1:2014 EN 60079-31:2014 |

||

|

Marked with

|

II 2 G D Ex db IIC T6 Gb Ex tb IIIC T80°C Db |

||

♦ MAIN CHARACTER of TSTLP Isolating/Lightning Spark Gap for Lightning Protection

1, For indirect connection / earthing of functionally isolated parts of installations under lightning conditions

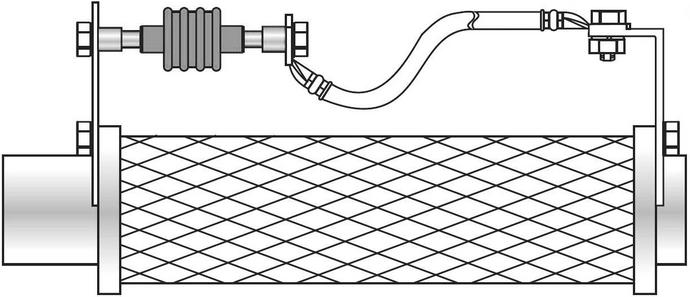

2, For bridging insulating joints, insulating (Pipeline) Flanges against damage caused by overvoltages, etc. in cathodically

protected pipe sections, to avoid failures, downtimes, and even leaks on pipelines and protect sensitive insulating

flanges against sparkover, which in turn to ensures smooth operation of the pipeline.

3, For safer installation in Ex zone 1 (gas) or 21 (dust)

4, Extremely low sparkover voltage & high alternating current withstand capability

5, Specially used for lightning equipotential bonding in Hazardous Areas

6, Approval according to ATEX directive 2014/34/EU, European Explosion-Proof Ex Certificate Available

|

INSTALLATION INSTRUCTION Applied for in-doors & out-doors,in damp rooms as well as underground installation. |

|

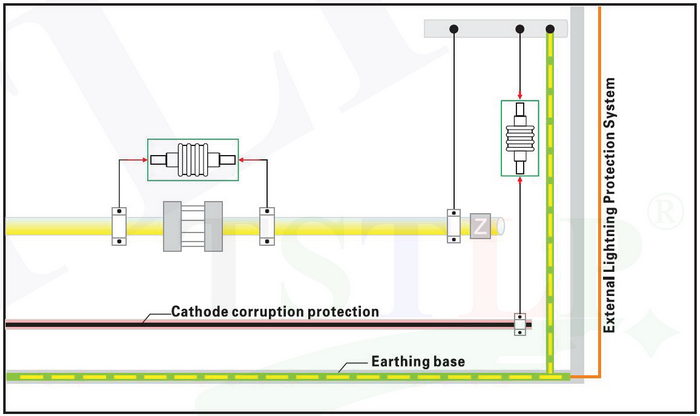

TSTLP Isolating Spark Gap Installation Diagram for Cathodic Protection (for reference)

INSTALLATION DIAGRAM of TSTLP Equipotential Connector (for reference)

|

|

WARNING: 1. The equipotential bonding connector must be installed by electrically skilled person, conforming to national standards and safety regulations. 2. It is recommended that installation of the spark gap earthing should be done under lightning/power off condition. 3. For safety, all grounding system should be connected together with no separation what so ever; If separated earthing system, there’s always a risk of potential difference between earthing systems. |

- KNOWLEDGE -

1- What's is Isolating Spark Gap (ISG) ?

- Based on gas discharge technology, component with discharge distance for isolating electrically conductive installation parts.

NOTE: In the event of a lightning strike, the installation parts are temporary connected conductively as the result of response of the discharge.

2- Isolating Spark Gap Function:

- Isolating spark gaps have been specially designed to isolate the electrical system for equipotential bonding connection (especially for the separated grounding systems for applying in Hazardous / Explosive Areas with Safer Lightning Impluse Protection), and TSTLP European Ex/ATEX directive certified isolating spark gap is one of the imperative device in surge protection as it serves the cathodic protection in oil and gas pipeline and the Cathodic surge protection device protects the equipment from corrosion. It works against the lightning and switching surges.

3- What is the Isolation Spark Gap used for ?

TSTLP Isolating Spark Gaps (ISG) are mainly used for lightning equipotential bonding Connection, Ex Areas for indirectly connecting/grounding/earthing functionally isolated installation parts under lightning conditions.

Isolating spark gaps for above-ground(above earth) & under-ground(under-earth) installation that are used to indirectly earth and connect functionally isolated parts of installations under lightning/surge conditions.

4- How isolating spark gap works (Working Principle):

- During normal operation, these high-impedance components act as open switches and ensure electrical isolation between pipe sections and earth/groud potential. If there is a voltage increase, the isolating spark gap changes to very low impedance – and at a defined response voltage, the switch' is closed.

Also refer isolating spark gap as spark gap surge protection or spark gap surge arrester or spark gap lightning protection.

- CONTACT US

0086 13926098193

0086 13926098193 0086 20 28819702 EXT 27806

0086 20 28819702 EXT 27806 [email protected]

[email protected]

Hongdiyuan Industrial Park, Wufeng Avenue, Linjiang Town, Jiangdong New District, Heyuan, Guangdong,P.R.C.

Hongdiyuan Industrial Park, Wufeng Avenue, Linjiang Town, Jiangdong New District, Heyuan, Guangdong,P.R.C. http://www.tslpro.com

http://www.tslpro.com +86 13926098193

+86 13926098193 F13926098193

F13926098193 tslpro.tstlp

tslpro.tstlp-